Laboratory panorama

After 27 years of development, the factory has developed over 12,000 products to date, covering more than 1,200 vehicle models. It is one of the manufacturers with the most comprehensive range of products for Japanese, Korean, German, European, and American vehicles in the domestic industry. The factory is developing over 700 new models annually (including more than 600 ball joint models and over 100 new arm models), keeping pace with the rapid updates and changes in the automotive market.

The company has two major production bases, Longfeng and Tianyu, equipped with a full set of high-standard production and testing equipment. All core components of the products are independently produced in-house. The factory's products are aligned with original equipment (OE) standards. The ball joints have passed 1 million gravity load tests without failure, and the bushings have passed 500,000 simulated bump road tests without failure. In 2015, the company committed to a "2-year/100,000 km quality guarantee," becoming the first company in the domestic aftermarket to make this commitment. Currently, the factory can produce 250,000 arms and 700,000 ball joints per month. Main equipment includes: 300T forging production line, 400T forging production line, Vertical drill, Sigma CNC machines, Taiwanese mirror polishing machine, Multi-station disc machine, Yizhiwei plastic injection molding machine, Panshi rubber injection molding machine, Shearing machine, Cutting machine, Hydraulic forming, Stamping machine, Panasonic fully automated mechanical welding machine (Japan), Laser cutting machine, CNC machining center.

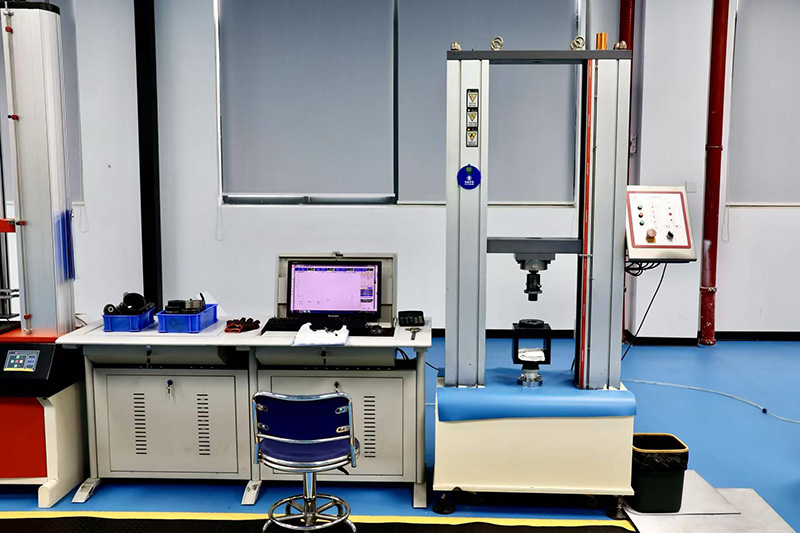

With 27 years of experience in suspension manufacturing, the factory has invested millions to establish a specialized laboratory. Equipped with over 30 types of testing and inspection devices, the factory conducts comprehensive and rigorous testing on every detail, from material to performance, and from durability to safety, ensuring strict control from all angles. Tianyu has kept the customer return rate below 0.4%. It is this obsessive attention to detail that has laid the unshakable foundation for the lean quality of Tianyu products.

Test the hardness of production materials

Test the durability and reliability of ball pins under multi-directional loads and high and low temperature coupling conditions

Check the durability and reliability of the triangle arm structure

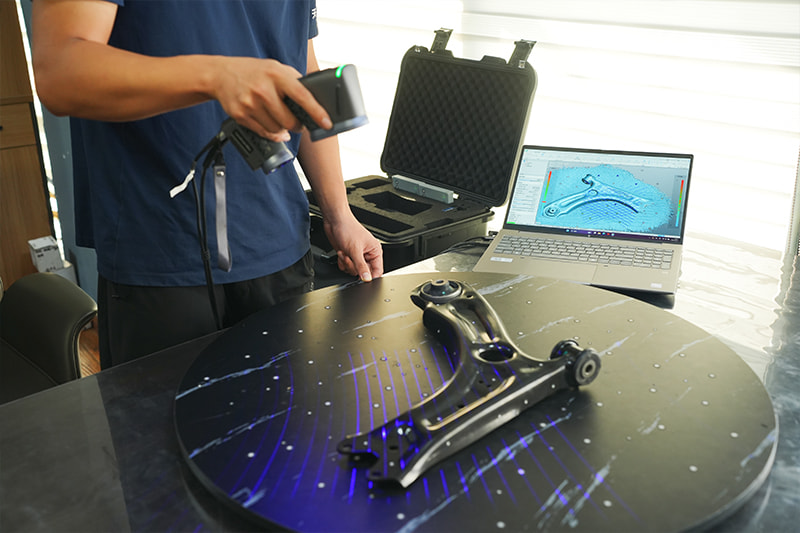

Provide more accurate data for products, tooling, molds, etc. than ordinary caliper testing, improving the accuracy of drawings and products

Test the ball head pull-off force, ball pin pull-off force, welding strength, and arm body strength

Test rubber quality and provide quality assurance for subsequent production of bushings

Test the corrosion resistance of materials in salt spray environment

Detect performance indicators such as starting resistance, rotation/swing flexibility, and fit clearance of ball pins under different torque loads

Test the durability and reliability of the bushing structure

Test the aging resistance of rubber materials in ozone environment

In 2023, the company transitioned from a manufacturing-based enterprise to a manufacturing service-oriented enterprise. Currently, the factory's warehouse maintains an inventory of over 2 million units: Yuhuan Factory holds 1.5 million ball joints (about 2,500 models) in neutral stock; Anhui Factory maintains 500,000 arms (about 600 models) in neutral stock. The inventory primarily consists of models for Japanese, Korean, German, and domestic vehicles. We support quick shipments of stocked models, with a wide variety and small batch sizes, ensuring rapid delivery within 7-10 days.