Auto Control Arm is a key component of the automotive suspension system, connecting the wheels to the vehicle body and controlling wheel movement to ensure suspension force transmission and vehicle stability. Tianyu (Anhui Tianyu Auto Parts Manufacturing Co., Ltd.) produces a wide range of control arms suitable for cars, SUVs, and light commercial vehicles. With advanced manufacturing processes and strict quality control, Tianyu ensures reliable performance and durability for every product.

Core Definition and Function

Material and Manufacturing Process Comparison

| Material Type |

Advantages |

Disadvantages |

Common Applications |

| High-Strength Steel |

High strength, fatigue-resistant, cost-effective |

Relatively heavy |

Passenger cars, SUVs |

| Aluminum Alloy |

Lightweight, corrosion-resistant |

Higher cost, slightly lower impact toughness |

Premium cars, performance SUVs |

| Composite Materials |

Extremely lightweight, corrosion-resistant |

High cost, complex processing |

High-performance or electric vehicles |

-

Manufacturing Processes: Stamping, forging, welding, heat treatment

-

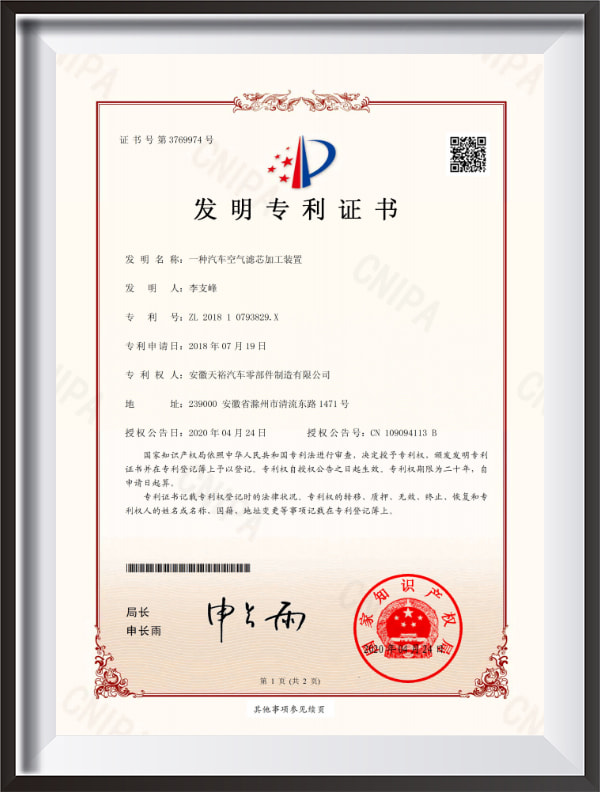

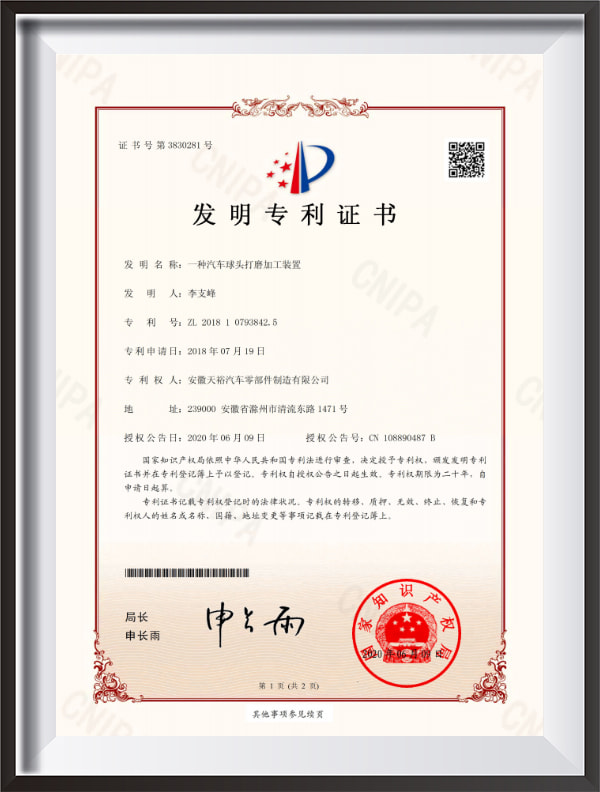

Quality Control: Tianyu is equipped with 60,000 m² of modern production workshops and a multi-million RMB R&D lab to ensure every control arm meets precision and durability standards.

Structure Type and Design Comparison

| Type |

Characteristics |

Application Scenario |

| Single Arm Control Arm |

Simple structure, easy to install |

Small passenger cars |

| Double Arm Control Arm |

High stability, strong load capacity |

Mid-size cars, SUVs |

| Multi-Link Control Arm |

Flexible wheel geometry adjustment, superior handling |

High-performance cars, luxury SUVs |

Key Components: Ball joints, bushings, mounting holes, connecting bolts

Design Considerations: Ensure suspension accuracy and wheel trajectory, optimize handling performance and tire wear.

Impact on Vehicle Performance

-

Handling Stability: Supports the suspension system to keep wheels stable and improve steering accuracy.

-

Driving Comfort: Bushings and ball joints absorb shocks, reducing road vibration.

-

Tire Wear: High-quality control arms ensure even tire contact with the road, extending tire life.

Common Failures and Symptoms

| Failure Type |

Common Symptoms |

Cause Analysis |

| Bushing Wear |

Noise, steering vibration |

Long-term use, material fatigue |

| Loose Ball Joint |

Unstable steering, bumpy ride |

Wear or loose bolts |

| Control Arm Deformation |

Vehicle pulling to one side, uneven tire wear |

Collision or overload |

Maintenance and Replacement Guidelines

-

Use products that match OEM specifications to ensure installation accuracy.

-

Tighten bolts according to torque specifications; ensure proper positioning of ball joints and bushings.

-

Regularly inspect bushings and ball joints, replacing worn or damaged parts in time.

-

Compare high-strength steel, aluminum alloy, and composite control arms to select the material suitable for vehicle performance requirements.

FAQ (Frequently Asked Questions)

Q1: What is the typical lifespan of a control arm?

A1: Depending on material and usage conditions, generally 5–8 years or around 100,000 km.

Q2: How can I tell if a control arm needs replacement?

A2: Look for symptoms such as steering vibration, unusual noises, uneven tire wear, or vehicle pulling to one side.

Q3: Which vehicles are Tianyu control arms compatible with?

A3: They cover a wide range including cars, SUVs, and light commercial vehicles, with support for small-batch, fast delivery orders.