Auto Rack End is a key component within the steering system, responsible for transmitting steering force from the steering rack to the tie rod, enabling accurate wheel angle adjustment during vehicle operation. As part of the steering linkage, the Auto Rack End is positioned between the rack housing and the tie rod end. It plays a structural role in maintaining steering stability and mechanical alignment, helping the vehicle achieve controlled directional response under varying road conditions.

Basic Definition and Function

The rack end consists of a threaded connecting rod, ball socket, and housing structure. Its core function is to convert the linear motion of the steering rack into the steering linkage movement needed for wheel turning. Through its internal ball-and-socket mechanism, the rack end provides controlled rotational flexibility while ensuring proper force transmission.

Structure and Key Performance Features

-

Ball-and-socket mechanism ensures precise movement within allowable angles.

-

Threaded connection supports secure installation and wheel alignment adjustment.

-

High-strength steel construction maintains rigidity under steering load.

-

Protective surface treatment enhances resistance to wear and corrosion.

These shared characteristics help ensure the Auto Rack End maintains stable steering performance throughout its service life.

Common Failure Symptoms

Rack end wear typically shows through:

-

Steering looseness or excessive play

-

Uneven or unstable steering response

-

Abnormal vibration or knocking noise from the front axle

-

Irregular tire wear caused by alignment deviation

Identifying these symptoms early can prevent additional steering system damage.

Service Life and Replacement

The service life of a rack end depends on road conditions, driving habits, and component material quality. Steering components generally require inspection every 30,000–50,000 km. When joint wear exceeds tolerance or when boots are damaged, timely replacement is necessary to maintain steering stability and vehicle safety.

How to Select and Maintain Auto Rack End

When selecting a rack end, factors such as compatibility, material durability, machining accuracy, and sealing performance should be considered. Routine maintenance includes:

-

Checking joint clearance and protective boots

-

Ensuring regular wheel alignment

-

Avoiding prolonged operation on damaged road surfaces

-

Using proper lubrication where applicable

For aftermarket users, choosing components manufactured under strict quality-control systems ensures stable performance.

Category Comparison

| Component |

Position |

Function |

Key Difference |

| Auto Rack End |

Between steering rack and tie rod end |

Transfers steering rack movement |

Mainly provides axial steering force |

| Tie Rod End |

At the wheel knuckle |

Connects linkage to wheel steering arm |

Provides rotational movement at the wheel |

| Control Arm / Ball Joint |

Suspension system |

Supports wheel movement and load |

Not directly involved in steering force transfer |

This comparison helps clarify the unique functional role of the rack end within the vehicle steering system.

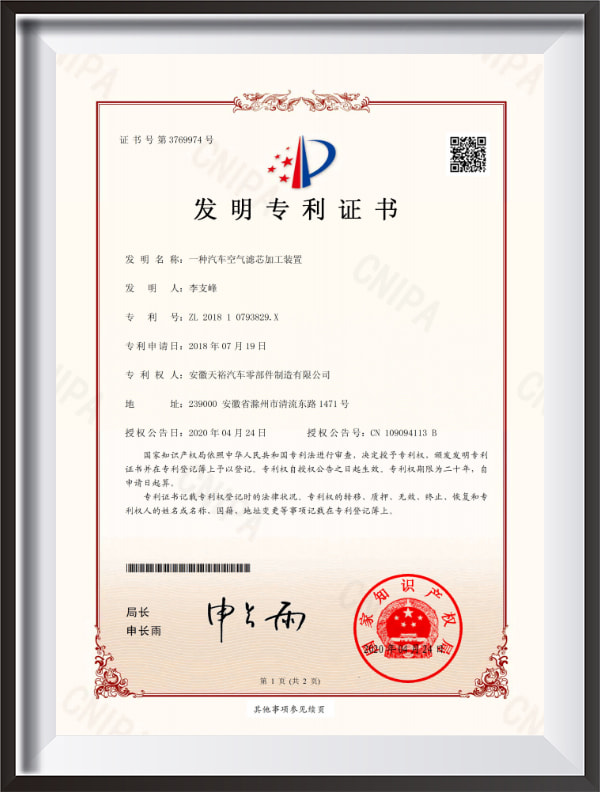

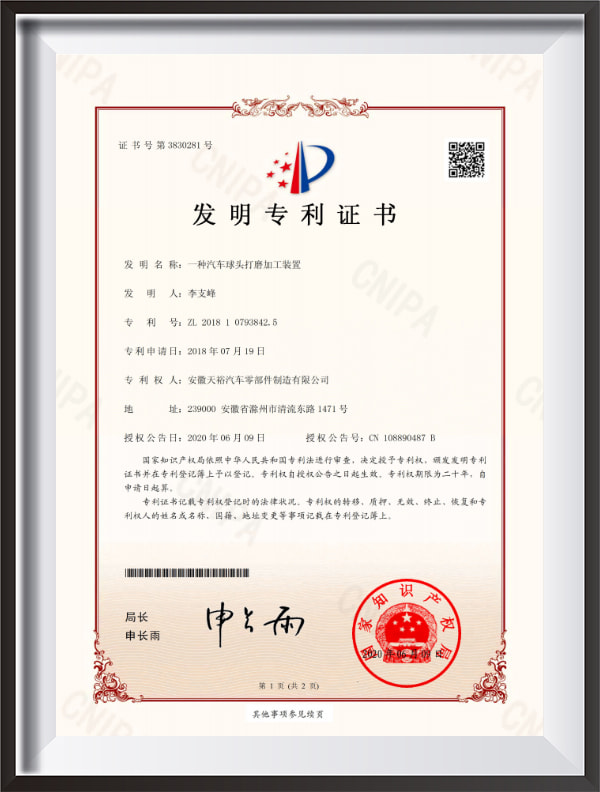

Anhui Tianyu Auto Parts Manufacturing Co., Ltd. provides a complete steering and suspension product range, including rack ends, tie rod ends, ball joints, stabilizer links, control arms, and bushings. With 27 years of manufacturing experience, modern production facilities, and a comprehensive distribution network, Tianyu supports diverse automotive aftermarket needs. The company maintains over 2 million units in stock and offers efficient 7–10-day delivery for small batch orders, meeting market requirements for stable supply and product variety.

FAQ – Auto Rack End

Q1: What is the primary role of an Auto Rack End?

A: To transfer motion from the steering rack to the steering linkage, enabling controlled wheel turning.

Q2: How do I know if the rack end needs replacement?

A: Signs include steering looseness, vibration, noise, or irregular tire wear.

Q3: Is the rack end the same as the tie rod end?

A: No. The rack end connects to the steering rack, while the tie rod end connects to the wheel knuckle.

Q4: How important is material quality?

A: Material and machining accuracy directly affect steering stability, service life, and safety.

Q5: Do rack ends require regular maintenance?

A: Yes. Inspection of ball joints, boots, and wheel alignment helps maintain optimal performance.